Description

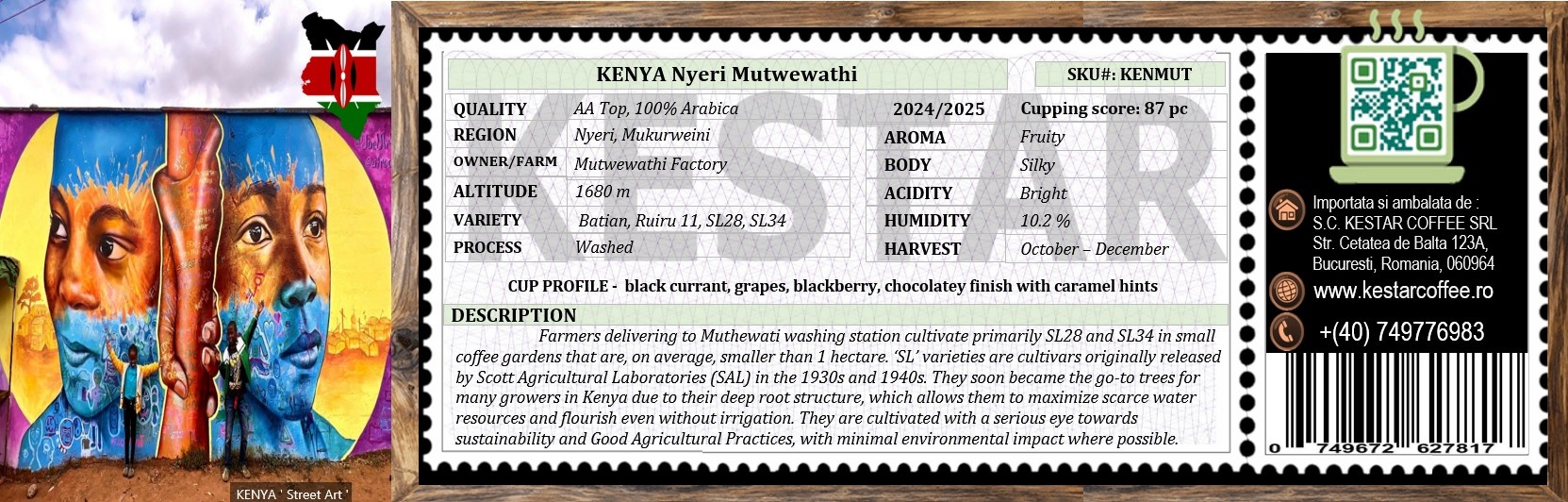

Processing: Washed; Cupping Score: 87 pts

Flavor profile with notes of blackcurrant, grape, blackberry, and a chocolaty finish with hints of caramel

ROAST PROFILE: Suitable for Espresso and Filter preparation.

GRINDING: Whole beans (Standard Delivery).

DEGASSING PERIOD:

- Espresso: 10-14 days

- Filter: 7 days

To provide you with freshly roasted coffee, at KESTAR COFFEE, coffee is roasted only on order and is available as whole beans (standard) or ground, delivered in special packaging with a degassing valve.

If you wish to receive ground coffee, before finalizing your order, please mention in the "ORDER COMMENTS" section how you prefer it: for espresso, filter, Turkish coffee, etc.

Processing: Washed; Cupping Score: 87 pts

Flavor profile with notes of blackcurrant, grape, blackberry, and a chocolaty finish with hints of caramel

Coffee cultivation in Kenya began relatively late, but quickly gained recognition for its quality and refinement. Over the decades, Kenyan coffee has become synonymous with excellence, celebrated for its complex aromatic profile, vibrant acidity, and meticulous processing methods. Today, more than 600,000 small-scale farmers—each cultivating less than five acres—contribute to nearly 70% of the country’s total production, organized into cooperatives that manage their own processing stations. In the Nyeri region, on the eastern slopes of the Aberdare Mountains, lies one such station: Mutwewathi Farm.

Mutwewathi Farm is part of the New Gikaru Farmers Cooperative Society, registered in 2001. The cooperative brings together over 4,600 active members and oversees five processing stations, including Ichamara, Thangathi, Kahuro, and Kiuu. Located in the Mukurweini sub-county, the farm benefits from an ideal terroir for cultivating Arabica coffee—high altitudes, fertile soils, and a temperate climate. Here, farmers grow varieties such as SL28, SL34, Batian, and Ruiru 11, each with unique characteristics that contribute to the diversity and quality of the coffee produced.

Cultivation is carried out with care and responsibility, in line with sustainable agriculture principles. The cooperative provides training in Good Agricultural Practices (GAPs), promoting methods that reduce environmental impact and enhance productivity. SL28 and SL34, developed in the 1930s–1940s by the Scott Agricultural Laboratories, are prized for their deep root systems, which allow them to withstand drought conditions and deliver high yields. Ruiru 11, a hybrid resistant to diseases such as Coffee Berry Disease and Coffee Leaf Rust, is favored for its high planting density and increased immunity. Meanwhile, Batian, with early maturation and disease resistance, is gaining popularity among growers.

Harvesting is done manually, with careful attention to the optimal ripeness of the cherries. They are delivered immediately to the processing station, where the “fully washed” method is applied. After sorting, the cherries are pulped, and the parchment beans are fermented in concrete tanks for 12–16 hours, depending on temperature and climate conditions. This is followed by washing and grading in channels with fresh water. During peak periods, the beans are soaked for an additional 24 hours to ensure thorough cleaning.

Drying takes place on raised beds and in solar dryers, over a period of 7 to 21 days. Throughout this process, the beans are frequently turned and covered during peak sunlight hours to prevent defects and ensure even drying. The resulting coffee is graded by size, with AA beans—the largest, measuring over 7.2 mm in diameter—considered the highest quality.

Mutwewathi Farm is not just a place of production, but a model of balance between tradition, innovation, and responsibility. Through the efforts of the local community and a strong commitment to sustainability, each coffee lot reflects not only the Kenyan terroir but also the passion and care of those who cultivate it.